Manufacturing accounts for 11.39% of the U.S.’s total economic output, according to the National Association of Manufacturers. And America’s growth in exported goods from 2010 to 2018 was up by an astounding 26.85%.

So there’s a lot of interest, and the American economic might invested in manufacturing.

And one of the most dynamic areas of manufacturing in the United States is in mass production.

Mass production has increased America’s ability to create products. It has also decreased production time and cost.

In the following article, we’ll look at mass production, how it works, and it’s future.

The Start of Mass Production

Mass production is the most efficient way to produce a large quantity of the same products. Before the Industrial Revolution, artisans worked in their homes and shops. Or they were employed by larger companies that mimicked the individual craftsman’s process.

With the Industrial Revolution, machines and factories took over for many traditional jobs. Weavers, tailors, and sewers were replaced by industrial looms and sewing machines, for example.

As this process evolved, standardized parts became a necessity. Instead of a craftsman produced individual parts, machine-tooled parts made in large quantities would fit a standard product line.

One example is a clock. A company would tool one mainspring and use it for its entire product line, even if the clocks were widely different in appearance.

This idea of the standardized part was an American one. Eli Whitney and Simeon North, both gun manufacturers, started using standardized parts in the 1800s. The idea quickly moved into all of manufacturing.

Eli Whitney, you may recall, was also the inventor of the cotton gin.

Assembly lines

The next step in mass production was assembly lines. And the basic concept was used for producing flour in 1874; it was Henry Ford in 1913, who became famous for developing the modern assembly line.

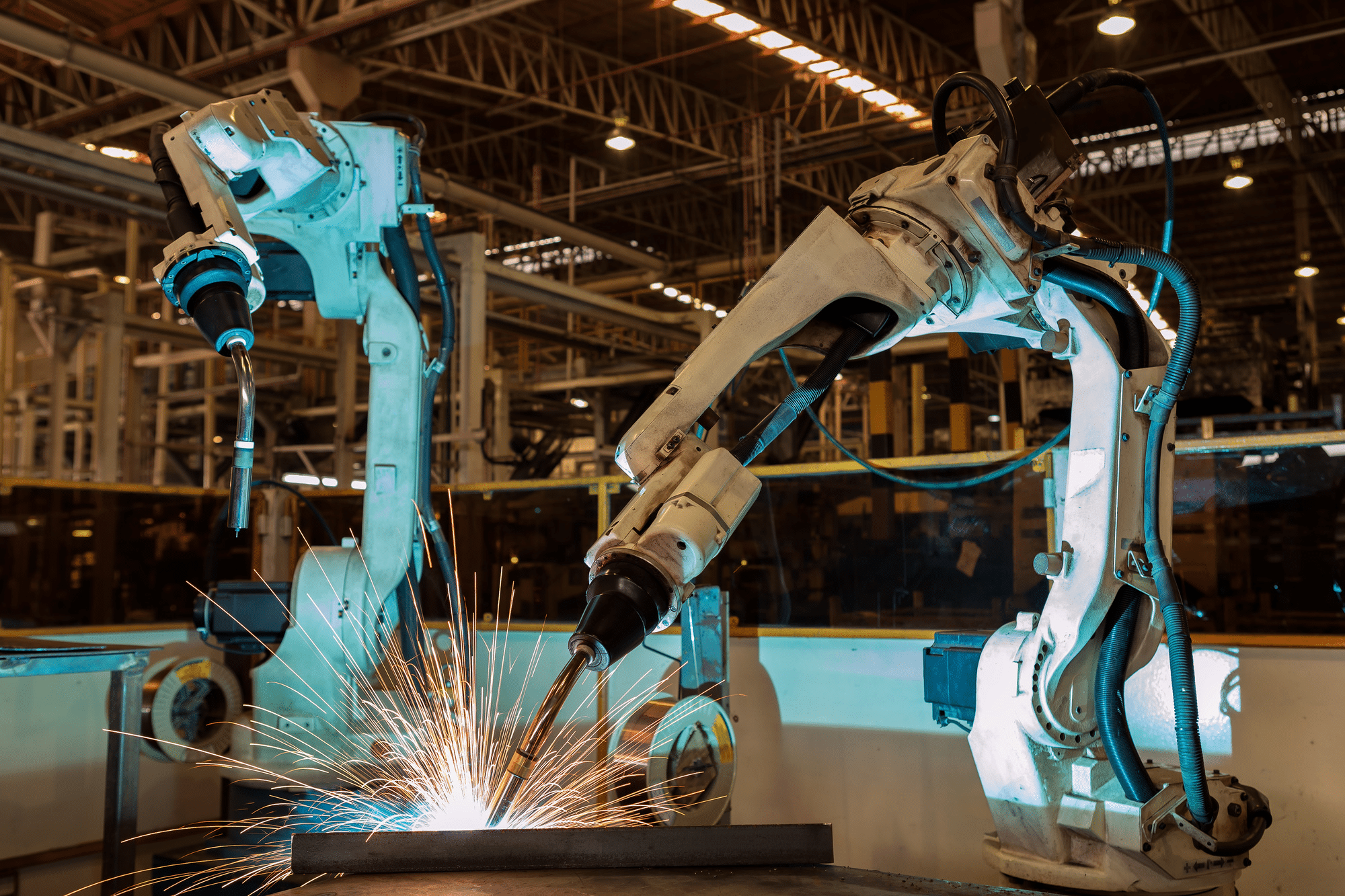

Today, assembly lines are a basic tenet of mass production, with highly sophisticated robots and computer-based artificial intelligence helping with the manufacturing process.

Today’s Mass Production

The mass production of auto parts and other state-of-the-art technologies is a major part of the American and world economies.

Shearing machines, hanging spot welders, and mechanical presses are just some of the machines used to create millions of parts through mass production.

Among the advantages of mass production, today include:

- A high precision rate

- Low production costs

- High-efficiency levels

Yet, there are a few downsides to mass production. The development of the mass production molds and machines to produce the parts can be expensive. Also, some workers find the production process boring and unsatisfying.

In the Future

Interestingly, although mass production and assembly lines were largely an American invention, many companies have outsourced these operations overseas.

Meanwhile, a new trend in mass production is on the horizon. These lean and efficient processes are now used to produce customizable goods in the U.S., and the reduced costs and improved logistics may spur the growth of more of the facilities in America.

Did you find this article of interest? Read more on manufacturing and design by searching this website.